HOME / Product information / WINDING-MASTER

We developed the high performance rewinder “WINDING - MASTER” which can be used for many purposes based on the technical know - how and manufacturing technology of the high-speed take-up winder and the high- speed Texturing machine by TMT machinery and TMT Kamitsu for many years.

In addition to making high-quality packages, easy operation is realized, and we will offer confidence as aproduct that will surely satisfy users.。

| MODEL | WINDING-MASTER |

| Applicable yarn | DTY, ATY, FDY, Mono-Filament (11 to 666dtex) |

| Winding speed | Max. 2000m/min |

| Package size | Max. ø250 (6kg) |

| Bobbin size | L:140-290mm, OD:50-77mm (Straight bobbin) |

| Package form | Tapered end cheese (Round shoulder ) |

| Feeding package size | Max. ø250 |

| Traverse system | Belt-traverse system Advanced precision winding |

| Bobbin-drive system | Bobbin directly driven system |

| Pressure-roll system | Pressure-roll swing system |

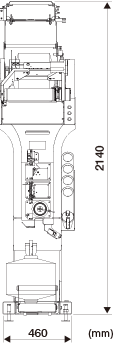

| Position pitch | 460mm |

| Supply power | AC 3 phase, 200-220V |

| Supply air | Min. 0.6Mpa |

| Options | ・Individual Auto Doffing device ・ Oiling device ・ Gate tensor ・ Cone winding ・ Package rotating feeding device |

1 Everything is possible

・ Polyester, nylon, rayon, others

・ FDY, DTY, ATY, twisted yarn, covering yarn, monofila, others

・ Soft winding for dyeing, Round shoulder winding, High density winding, Other

2 Unique CR-mechanism

・ CR-unit supported movably

・ Contact pressure control by cylinder and regulator

・ Stable low contact pressure required for soft winding

3 Precision traverse control

・ Variable winding width by belt traverse

・ Advanced unique precision winding

・ Uniform and perfect PKG quality

4 Unique feeding system

・ Yarn feeder vertically (rotation unwinding & depolarizing)

・ Securing unwinding length by guide bar

・ Improved workability with pull-out type yarn stand

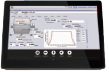

5 Easy operation and settings

“ Easy setting” function according to purpose

・ (+) (-) adjustment function

・ Storage function of winding result (shape, density)

6 Flexible layout

・ Winding unit is mechanically and electrically independent

・ Operation is possible by simply connecting the power supply and Air

・ Optimum layout possible